Product Analysis

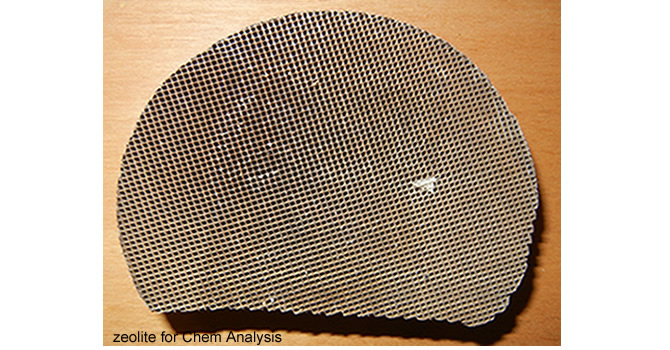

We perform testing and analysis on a variety of products including raw materials, semi finished and finished products and components in accordance with a number of national and international specifications including the American Society for Testing and Materials (ASTM), the American Society of Mechanical Engineers (ASME), British Standards (BS), German Standards (DIN) and Bureau of Indian Standards (BIS). We also perform client tailored test to suit and correlate our clients’ product service and application conditions.

We perform testing and analysis on a variety of products including raw materials, semi finished and finished products and components in accordance with a number of national and international specifications including the American Society for Testing and Materials (ASTM), the American Society of Mechanical Engineers (ASME), British Standards (BS), German Standards (DIN) and Bureau of Indian Standards (BIS). We also perform client tailored test to suit and correlate our clients’ product service and application conditions.

FAN is an independent third party materials testing laboratory with over 30 years of industry experience in materials and product testing and analysis. Our interdisciplinary team with a broad knowledge and industry experience can guide you through the maze of existing national and international regulations to ensure that your products receive the right certification in a timely and cost-effective manner.

Importance of Product Testing

- To get third party certification and testing

- To obtain compliance certification

- To ensure that quality standards are being met

- To file patents and other legal rights

- To have competitive advantage over competitor’s product

- To develop novel & cost effective ways of achieving required quality

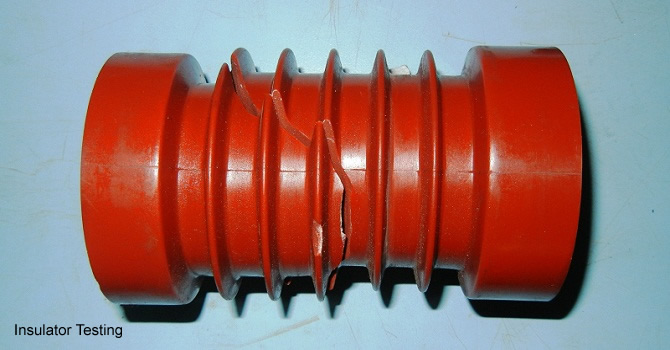

- To predict the modes of failure and to take preventive steps

The importance of incoming raw materials testing can not be undermined at any stage and instance. Raw material forms the basis of the overall quality of the finished product. If appropriate and timely testing of raw material is not done then it may lead to

- Poor incoming raw material quality

- Tool wear and damage

- Wastage of productive time, energy and money

- Poor finished product

We offer comprehensive one stop and cost effective testing solutions specifically to meet your industry needs. We offer services in almost every sector of the industry.

It is highly recommended that you perform testing at intermediate stages of manufacturing / processing to evaluate your product quality and to make necessary changes if needed. This approach can result in to a lot of savings along with the delivery of the required quality.

Finished product certification not just ensures the trust of your customers on to your product but also gives you a better understanding as to the quality of your product and the necessary steps needed to achieve the required quality.